Services

Quality and Inspection

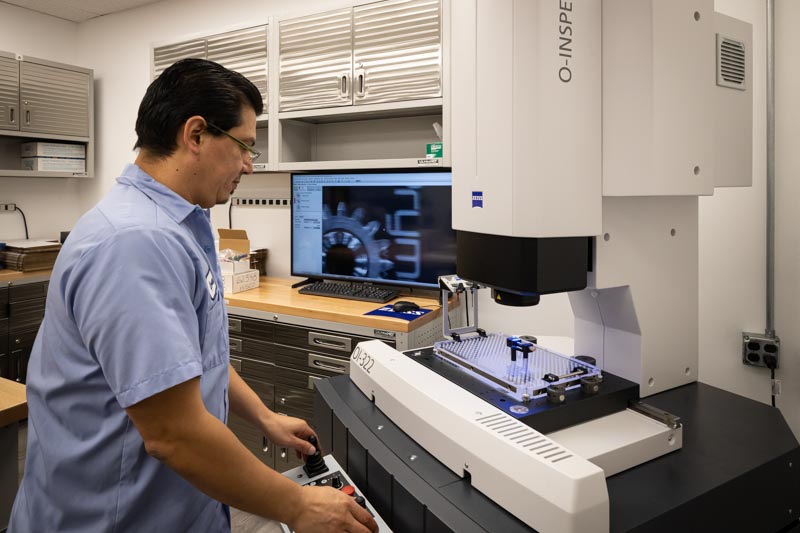

At Roberts Swiss, we’re serious about quality. Our Quality Assurance Department uses the most advanced analysis and inspection technologies to ensure perfect parts every time.

Quality Assurance

The OGP Smartscope provides fast, programmable inspections of complex part cross-sections accurate to one micron. Our quality management system is based on the International Standards Organization (ISO) 9001:2015 and ISO 13485:2016. It’s fully audited and registered with an ANSI/ANAB accredited registrar.

The OGP Smartscope provides fast, programmable inspections of complex part cross-sections accurate to one micron. Our quality management system is based on the International Standards Organization (ISO) 9001:2015 and ISO 13485:2016. It’s fully audited and registered with an ANSI/ANAB accredited registrar.

All company processes and procedures are documented in our published quality manuals. Gages are owned, controlled, and calibrated by Roberts Swiss Inc.

Statistical Process Control (SPC) Capabilities

As our manufacturing is highly technological, our Quality Assurance Department also utilizes the most advanced technologies. Statistical process controls (SPC) data is processed via the latest networked version of Datalyzer Spectrum SPC software.

Assessments and analytical studies are available using Minitab Statistical software. Vision system analysis is available via QC-Calc. With these technologies, our quality team can effectively inspect and analyze data to develop the following:

- Quality assessments

- Production part approval processes (PPAPs)

- Supplier part approval processes (SPAPs)

- Process control charts

- Process capability histograms

- Gage R&R studies

- Process failure mode and effects analyses(FMEAs)

Measurement Capabilities

Our measurement capabilities range from the smallest component dimensions in thousandths to part dimensions measured in inches. Our measurement equipment ranges from handheld gauges to optical comparators. We use Keyence and Oasis inspection, and OGP Vision system with CMM contact capabilities, and Zeiss CMM with multi-function capabilities (lighting and contact probing).

This state-of-the-art technology allows us to deliver exceptional measuring speed and flexibility, while avoiding the "speed versus accuracy" compromises inherent to more conventional techniques.

Quality Integration

At Roberts Swiss, quality is integrated throughout our engineering and manufacturing operations. 3D models flow between departments to help design, manufacture, and test components in the most efficient manner possible.

This quality integration ensures the development of inspection processes that are consistent with our client’s needs while also facilitating the manufacturing process.